Bauer Maschinen and the Harren & Partner Group have established a joint venture to combine and enhance their expertise in the seabed mining sector.

The joint venture company, Seabed Mineral Services, will initially work to determine the economic viability and, in particular, the environmental compatibility of what it describes as the ‘vertical approach’ to seabed massive sulphide (SMS) recovery.

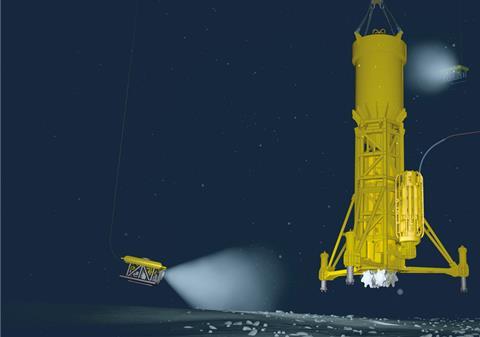

SMS, found at the bottom of the deep sea, are a valuable raw material. The vertical approach is a method for extracting these materials using the trench cutter method – an established technique in specialist foundation engineering that is operated and supported in the from a ship on the open sea. As a relatively small-scale intervention with a minimal ecological footprint, this approach is an ideal method for test mining and exploration of deposits up to a depth of 3,000 m.

“We are thrilled to have found an expert partner in Bauer who is willing – just like us – to seize opportunities and take on a pioneering role in the field of deep-sea mining. Our joint approach for this venture is based on a combination of established technologies. This enables us to minimise the technological risk while at the same time keeping costs down,” said Heiko Felderhoff, managing director of Harren & Partner.

Leonhard Weixler, head of the diaphragm wall equipment division at Bauer Maschinen, added: “The chemistry between us is very good; we share a similar spirit. This partnership is an ideal union of specialist knowledge and experience in the afield of offshore technologies and services with expertise in the development and production of specialist foundation engineering equipment for onshore and offshore customers around the world.”

Felderhoff and Leonhard Weixler act as managing directors of Seabed Mineral Services.

The technicalities behind the vertical approach are designed to minimise damage to sensitive seabed ecosystems – particularly stirring up sediment. To prevent fine material from escaping the cutting area, a protective collar is positioned around the cutting wheels at the start and the actual cutting process is protected by the surrounding ore. As a result, fine material from the cutting process remains within this area, while the water mixed with fine sediment and cutting chips is pumped into the ore container.

The separation process is carried out within the ore container to separate the particles from the sea water via sedimentation. After this treatment, the water is fed back to the cutting wheels and reused in the cutting circuit. This closed system minimizes the volume of sea water that is impacted by the cutting process.

Another aspect of the vertical approach that reduces the environmental impact method compared to other methods is that only one tool is used for extracting material. The soil does not need to be crushed later for transport to the ship; only the raw material is extracted, with minimal impact on the environment.

Germany-headquartered Bauer Maschinen Group is a leading player in the development and manufacture of specialist foundation engineering equipment.