USA-headquartered machinery manufacturer Enerpac has released its LHS4-2 skidding system, which can jack and slide loads up to 400 tons (362.9 tonnes).

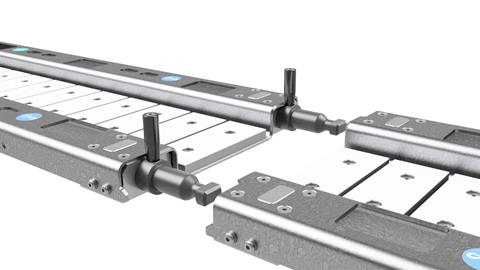

Backwards compatible with the earlier LHSS400 skidding system, the LHS4-2 features an updated track coupling systems – with no tools required – and longer tracks that allow for quicker track assembly.

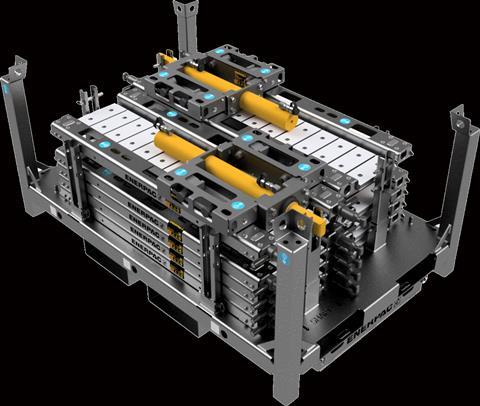

The low-height skidding system’s modular design contains a series of skid beams, a skid track and hydraulic push-pull units. The LHS4’s starter kit includes 10 skid track units – enough for two lines of 7 m each – as well as two push-pull units, four skid beams, handling tools and the transport frame. A skid track kit is also available and comprises a transport frame and 14 skid tracks for two 10 m lines.

Friction of loads are reduced by polytetrafluoroethylene-coated pads placed on the skid tracks. The skidding system’s push-pull cylinders are powered by a standard Enerpac split flow pump to ensure each skid beam travels synchronously, which also allows bi-directional operation without needing to reposition the cylinders when switching skidding direction.

Instead of the bolting joint used for the earlier skidding system, the LHS4-2 uses a simple hand twist motion to connect the track together. The updated model’s track lengths have increased from 955 mm to 1,433 mm, with this factor and the hand twist motion allowing for a quicker and easier assembly and disassembly. New skid track handling hooks provide a more ergonomic assembly, while the LHS4-2’s steel transport frame boosts transportation and storage safety.

HLPFI reported earlier this month that Petrodec had deployed an Enerpac ETR115-SO trolley system for decommissioning work.