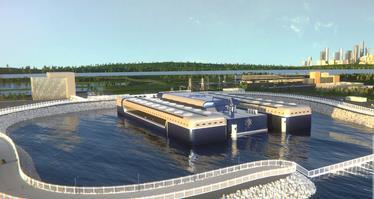

NuScale Power and Prodigy Clean Energy have revealed a concept design for a transportable, marine-based small modular reactor (SMR) power generating facility.

According to NuScale, the nuclear power solution provides improved transportability, manufacturability, economics, safety, and security.

Similar to the NuScale VOYGR SMR power plant, Prodigy’s SMR marine power station (MPS) is scalable, being able to house from one to as many as 12 NuScale power modules for a total output of 924 MW. After transport to the deployment location, the marine facility would be fixed in place within a protected harbour and connected to shoreside transmission and process heat systems.

Nuclear fuel would be loaded in the NuScale power modules as the last step of the commissioning process before beginning power generation. Operations, security, and fuel handling protocols are equivalent to those used for a traditional nuclear power plant under existing nuclear regulations. At the end of its life, the marine facility would be transported to a marine-accessible centre for decommissioning.

“NuScale is extremely proud to continue this partnership with Prodigy, as utilisation of a transportable marine facility will enable us to deploy the NuScale power module at more locations around the world,” said John Hopkins, NuScale Power president and ceo. “By combining Prodigy’s technologies with NuScale’s safe, scalable, and innovative SMR design, we are confident in our ability to deliver our carbon-free and cost-competitive SMR technology globally.”

“By packaging the NuScale power module into Prodigy’s marine facility, we will offer countries a near-term solution to address energy security and to decarbonise their economies, including replacing coal-fired plants – many of which are located at the coast,” said Mathias Trojer, Prodigy Clean Energy president and ceo.

Compared to terrestrial deployments, the benefits of using the marine solution begins with manufacturing and outfitting of the entire marine facility in a shipyard, enabling expedited delivery. According to NuScale, further advantages include a significantly reduced capital expenditure; accelerated project schedule; minimised site preparation; reduced environmental impact; unlocked project financing structures that are not typically available to conventional site-constructed nuclear plants; and simplified and expedited decommissioning and site recovery.

The marine facility’s design is standardised to allow for deployment at a wide variety of sites and for serial manufacturing.