Enerpac’s SyncHoist lifting systems are assisting in the assembly of a vacuum vessel for the ITER power project in southern France.

ITER is a collaboration between 35 nations to build the world’s largest tokamak – a cutting-edge system designed to prove the feasibility of generating electricity on a large scale from nuclear fusion rather than fission. It is located on a 180 ha site in Saint-Paul-lez-Durance.

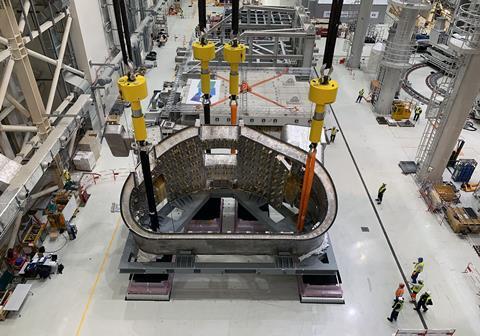

Enerpac’s SyncHoist system is being used to lift 500-tonne vessel sections into an up-ending tool for vessel assembly. The SyncHoist system comprises four double-acting, push-pull cylinders connected to lifting points.

The vacuum vessel comprises nine sections made of special grade stainless steel. Each section is 13 m high, 6.5 m wide and 6.3 m deep. Four 225-tonne capacity SyncHoists assess the centre of gravity for each section prior to the lifting operations.

“SyncHoist allows us to know the load at each lifting point and control the lift precisely with a 1 mm accuracy,” said Jarl Buskop, assembly engineer, sector modules delivery and assembly division at ITER.

In addition to the vacuum vessel sections, the SyncHoist lifting system will be used to lift toroidal magnet field coils for insertion in the vacuum vessel.