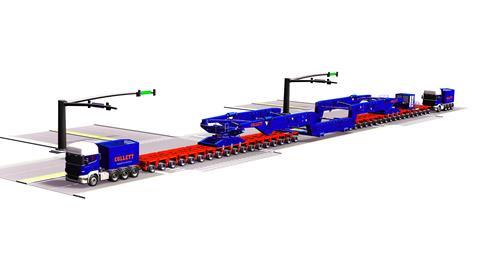

Described as the ‘missing piece of the puzzle’, heavy haulier Collett & Sons has added a 350-tonne capacity modular side girder bridge system (SGB) from Germany-based manufacturer Greiner to its fleet.

Bolstering Collett & Sons’ high and heavy cargo handling capabilities, the SGB will initially be deployed for a long-term contract moving transformers from Stafford to Ellesmere port, both in the UK. Greiner’s SGB sits between Collett & Sons’ current 150-tonne, 250-tonne, and 500-tonne capacity trailers.

“This new 350-tonne Greiner [girder bridge system] sits comfortably in a sweet spot in the market and truly is the ‘missing piece of the puzzle’, strengthening our heavy transport capabilities and giving us even greater flexibility to meet the evolving demands of our clients,” said David Collett, managing director at Collett & Sons.

The SGB features fully interchangeable neck and deck beams, with the modular design allowing for the system to be configured for varying axle combinations, ranging from 2 x 8 to 2 x 18 rows. By combining different beam components, the side deck length can be adjusted from 3 m to 18 m.

Highlighted for its flexibility, the Greiner SGB can accommodate several transformer loading methods in accordance with their manufacturer specifications, including high shoulder/trunnion support (high deck); low shoulder/trunnion support (low deck); full bottom support (cross beam); and toe support (inside beam toe). This helps mitigate the issues posed by headroom when transporting high and heavy loads.

Deck beams are not required as the girder bridge features a Z beam connector, which allows the neck beams to link directly to specially designed loads. Meanwhile, the system has a hydraulically adjustable internal loading aperture, ranging from 1.8 to 4.6 m and its full hydraulic system enables deck height adjustment with a stroke capacity from ground level up to +1.9 m.

Earlier this month, Collett & Sons purchased 36 G6 THP/SL-L modular axle lines from Goldhofer.