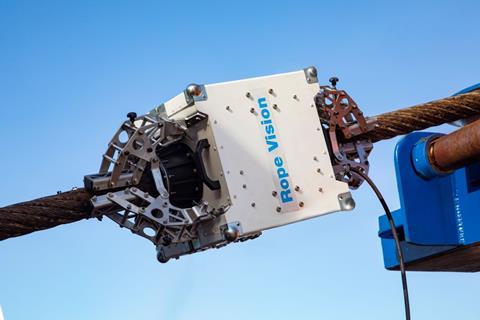

Huisman has launched an advanced automated visual inspection tool designed to enhance the reliability and safety of wire rope operations.

Specifically aimed at wire ropes for heavy lift cranes, Rope Vision integrates high resolution visual scans with crane controlled measured usage data, enabling predictability of the remaining wire rope life expectancy and supporting timely maintenance planning.

Huisman said that by measuring and analysing key parameters including lay length, diameter, broken wires and protrusions, a severity rating (based on ISO 4309 standards) is given to the wire rope. This data-driven approach enhances safety, extends wire rope lifespan and improves asset efficiency by enabling precise anticipation of maintenance needs and reducing unforeseen downtime, it said.

Martijn Reissenweber, director services at Huisman said: “Rope Vision represents a significant step forward in how we manage wire rope integrity. This is more than just a new tool, it’s a strategic shift in how we leverage automating inspections and intelligent data analysis. Instead of reacting to wear and tear, we offer the possibility to schedule maintenance proactively.”

Key features of the system include four high-speed 1,024-pixel cameras offering a 360-degree view and a scan speed 45m/min. It is suitable for 50-72 mm diameter wire ropes.